Wellden

Thermal Paper & Thermal Label

Thermal Paper & Thermal Label

Thermal paper is a special fine paper that is impregnated with a chemical that changes color when exposed to heat. It is used in direct thermal printers and particularly in cheap, lightweight devices such as cash registers, POS, ATM and credit card terminals. The coating will turn black when heated. But coatings that turn blue or red are sometimes used.

*The pigmented pre-coats that are applied to the base paper are a feature of thermal papers, They are vital if the thermal coat on top is to work perfectly. The thermal coat contains the chemical components that generate the image through point heat transfer by the thermal printer. Further protective coatings on the front and back give the thermal coat additional protection against chemical influences and optimize the properties of the product with regard to a wide variety of specific requirements such as printability, lamination, etc.

Most direct thermal papers require a protective coating to:

- reduce fading of the thermal image caused by exposure to UV light, water, oils, grease, lard, fats, plasticizers, and similar causes.

- provide improved printhead wear.

- reduce or eliminate residue from the thermal coating on the thermal printheads.

- provide better anchorage of flexo or offset printing inks applied to the thermal paper.

- focus the heat from the thermal printhead on the active coating.

Advantages:

- Cost saving (economy) : non moving print head (less wear and tear), no drum, no dot matrix ribbon, no toner, no ink, only need to change print head once in a few years

- Easy to use

- Quiet and fast (compare with dot matrix, double the print out speed)

- Energy saving (less moving parts compare with dot matrix)

- Low maintenance (only need to change paper)

- Compact printer (idea for portable hand-held terminal)

Disadvantages:

- Image get faded after a period of time

- The need for making photocopies on important receipts or documents which will incur additional costs (apply to commodity grade only)

Image durability

For every grade of thermal papers, it grant a certain life span for the thermal image. The lifespan of the thermal image is based upon a set of optimum storage conditions and a fully developed thermal image. Under these conditions a thermal image will last anywhere between 1 year up to 25 years depending on the grade. The reality of day-to-day use is that thermal paper is not stored in perfect conditions. The paper is often subjected to conditions that can be destructive to the thermal image and/or image contrast. It is therefore important that a suitably stable grade be selected for the end application.

Storage conditions

As with office paper, thermal paper should be stored indoor, at temperatures between 18°C and 24°C and with a relative humidity of 40% to 60%. Storage of un-imaged thermal paper under these conditions will assure satisfactory performance for at least 3 years from the date of manufacture. Longer term storage at temperatures over 40°C or over 65 relative humidity can lead to a reduction in image contrast or performance of the thermal function.

Handling conditions

Direct sunlight, fluorescent and similar UV light sources should be avoided. As the contrast of the printed image can be reduced or destroyed depending on the duration of contact, thermal paper should not come into contact with,

- Carbon and carbonless forms

- Wet-type diazo copy paper

- Chart papers or adhesives containing Tributyl-phosphate, Dibutyl-phosphate or other organic solvents

- Envelopes or folders composed of plastics containing plasticizers

- Solvents or solvent-containing products, which include Alcohol, Ketones, Esters, Ethers or derivates from this chemical group

- Petroleum solvents like Gasoline, Toluene or Benzene

- Greasy substances like Lanolin (eg. Hand-lotion), Lard, Butter, Oil or Vegetable Oil

Application for Cash register rolls, Fax rolls, Banking Receipts, Utility Bills, Medical Papers, Transportation Tickets, Entertainment Tickets, Gaming Tickets, etc

Image color

mainly black but sometimes blue or red (other colors possible upon special request and MOQ)

Paper weight ranging from 48gsm up to 240gsm:

- POS/ Fax grade (48gsm – 80gsm)

- Thermal Label (70gsm – 80gsm)

- Thermal Ticket (80gsm – 240gsm)

Wellden

Type of Thermal Papers

Standard grade

Standard sensitivity and image durability from 1-7 years application for POS receipt roll, Fax paper, ATM roll, Q-matic roll, Toll receipt, etc

Long life grade

Improved resistance against environmental influences such as heat, humidity, light, lanolin, ethanol, plasticizer and water. Longer image durability from 8-25 years application for Medical paper, Utility bill, Credit card receipt, etc

Advantages:

- Recent trends in certain market have caused new demand for long life thermal papers. The main factors are compliance to Income Tax Self Assessment System whereby receipts for tax deduction should be kept for 7 years. If faded, it would cause a lot of misery or problems to the tax payers.

- Eliminate the need for making photocopies on important receipts, which will incur additional costs.

- Banks and Financial Institutions will require long life thermal papers for their payment terminals and transaction receipts for compliance to the Banking Act. Journal rolls in ATM need to be kept for 5 years in Malaysian Banking Act and as such, banks start to ask for warranties and better quality thermal paper from their suppliers.

- Market still in the infancy stage, it is highly potential to capitalize on this area as the only direction is for the demand to go up as we are starting from almost zero base (sales cannot be negative).

- Possibility of high profitability for pioneer company who introduce into the market.

- We offer long life thermal grade with a cost difference from the current standard of only 5 - 15% depending on size, quantity and years image preservation is needed. Please note that although the current standard thermal is suppose to last 1 year, the mills only give this warranty under severe lab conditions but not under normal real life temperature and humidity conditions. The standard thermals tend to last not more than 1 year under real life environmental conditions.

- Most customers who select these long life grades would tend to view your company as the premium supplier rather than being just a normal commodity supplier.

High density

High sensitivity print application for Medical paper, Utility bill, Handy terminal receipt, etc

BPA Free contains

Manufactured without the use of synthetic chemicals, which traditionally used as a coating. BPA Free Thermal Paper does not contain BPA and it is free from any transference of the chemical substance from the paper into human bodies

Top-coated

Top-coated grades are more resistant to oil/grease, alcohol and plasticisers but images can still be affected with prolonged exposure. High reliability on scratch protection, very good topcoat printability and very good barcode scanability application for Lottery ticket, Gaming ticket, Packing ticket, Boarding pass, Baggage tag, Train ticket, Admission ticket, Entertainment ticket, etc.

Specialties

2-color thermal paper, 2 sided thermal paper, Synthetic thermal paper, Color Inlay thermal paper.

Testing method

- Water Test (dip paper into water for different hour to see the image appearance

- Alcohol Test (25% alcohol strength solution apply to thermal surface)

- Oil Test (apply cooking oil on thermal coating)

- Hand Lotion (apply the lotion on thermal coating and leave the paper for 24 hours. Observe the image appearance after 24 hours)

- Plasticizer (using Tesa tape to stick on the thermal paper and observe the image appearance after 24 hours)

- Heat Test (put the printed thermal paper on the machine and apply different temperature. Take the density reading)

- Lighter Test (to check image color, white spot and determine the coating on thermal ie, printout consistently have an unprinted line, therefore need to check whether is printhead or thermal coating problem)

- Wet Rub Test (normal Flexo print out, the ink come out with water rub)

Testing Equipment

- Weighing scale (measure paper gsm)

- Caliper (measure paper thickness)

- Densitometer (measure image density) : take average of 5 reading, good quality image will have not less than 1.2dE

Thermal Sensitivity

2 types of sensitivity measure

-

Static sensitivity (temperature at which a thermal paper will begin imaging)

Low static sensitivity = High imaging temperature

High static sensitivity = Low imaging temperature -

Dynamic sensitivity (how fast a thermal paper can be imaged)

High dynamic sensitivity = Faster printer

Low dynamic sensitivity = Slow printer

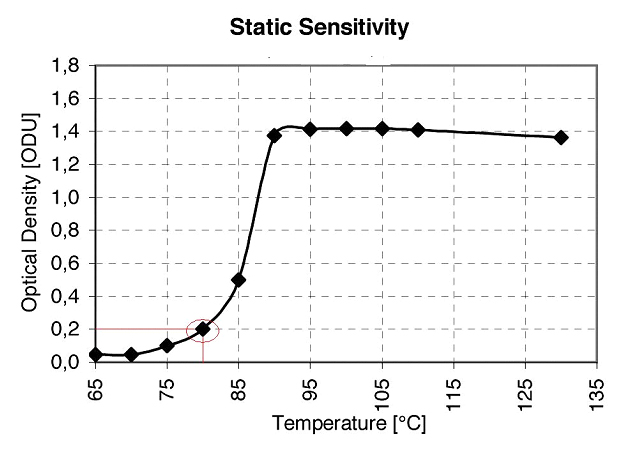

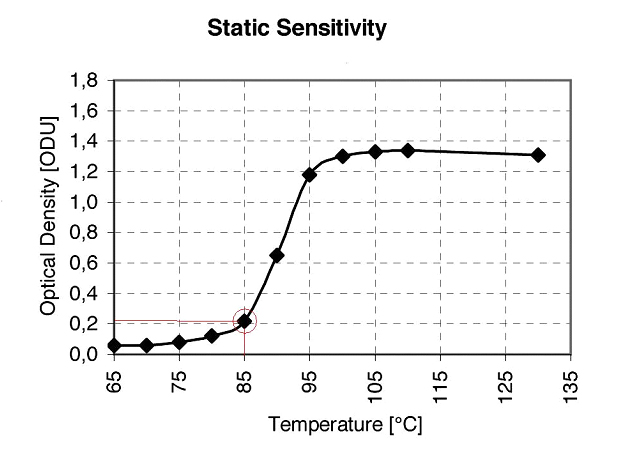

Comparison of Static Sensitivity,

In regards to static sensitivity, it is refer to the temperature where the image start to emerge. Therefore, thermal paper from chart 2 has the higher static sensitivity compared to thermal paper from chart 1 as the image appears at lower temperature (80ºC compared to 85ºC).

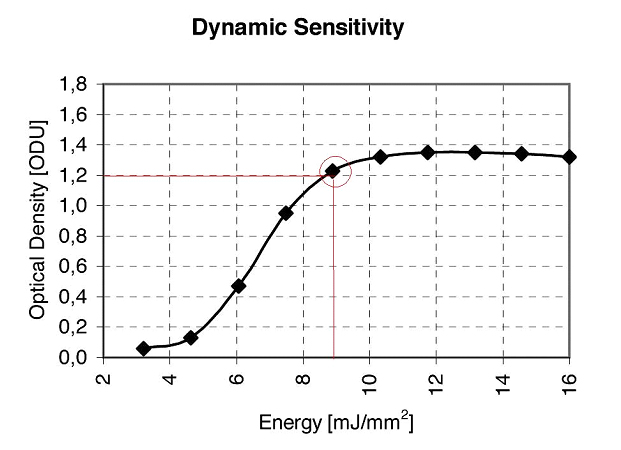

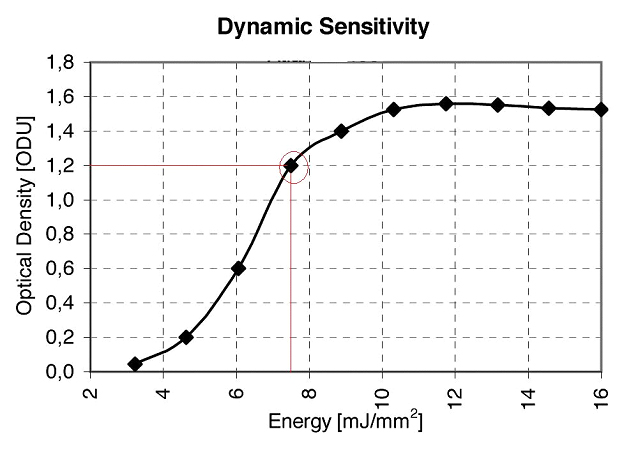

Comparison of Dynamic Sensitivity,

Refer to chart 1 and 2, at the same optical density of 1.2 ODU, thermal paper from chart 2 needs lesser energy compared to thermal paper from chart 1 to make the image appear. Therefore, thermal paper from chart 2 is more sensitive in term of dynamic sensitivity. The printability will be faster by using thermal paper from chart 2.

Product Measurement

Width(mm) x Roll OD(mm) x Core ID - paper roll sell by roll diameter (recommended to use thicker or higher substance paper for cheapaer roll cost reason)

Width(mm) x Length(M) x Core ID - paper roll sell by roll length (recommended to use lower substance paper such as 48gsm paper)

Thermal Paper Mills

- European Thermal Paper - Grade A and B product

- Japanese Thermal Paper – Grade A product

- Korean Thermal Paper – Grade A product

- USA Thermal Paper – Grade A product

- China Thermal Paper – Grade A, B and C product

Disadvantages of using Grade C thermal paper

- No warranty will be given to their rolls, no refund on damages and deformities of the rolls.

- These papers have not been fully tested by any major OEM thermal printers manufacturers.

- No after sales service, if there are any problems the supplier will not assist in solving them.

- The rolls tension and the length is inconsistent.

- Risks involved are high as sometimes you will not receive the goods after paying the deposits.

- Lost of company reputation and branding if there is any quality claims

POS/ Fax – POS (Point of Sale) offers all sorts of possible applications whether from a retailer, coffee bar, petrol station or supermarket, most receipts are printed on thermal paper. Fax papers also represent an important area of application for thermal papers.

Label – Labels are an indispensable means of communicating information about a product. Generally speaking, the relevant data is carried by a barcode, which can be scanned using a reader. The print image has to be correspondingly clear and pin sharp.

Entertainment – The paper used for what are frequently brightly printed admission tickets has to be top quality. Excellent printability, extreme stability and durability are vital criteria. The key term “security features” also plays an important role in ensuring that admission tickets cannot be copied easily. Reasons enough to rely on thermal paper.

Transport – Used throughout the transport industry, including for airline tickets, baggage tags, bus, train and ferry tickets, parking tickets and toll receipts. In particular, it is used for ATBs (Automated Ticket and Boarding Passes). Virtually all airlines belong to this association, which is the governing body for international air transport. Only companies that fulfil the IATA recommendations may supply the papers for boarding pass.

Gaming – There are strict requirements for lottery tickets and betting slips. The paper must have excellent printing properties, cope well with high-speed printers and be highly durable.

Banking – State-of-the-art self-service machines such as ATMs, statement printers and multifunction terminals – and with them thermal paper – are now a fixture in bank foyers. The manual receipt that used to be provided by the cashier is now printed out automatically, usually on high-grade, stable and extremely durable thermal paper.

Medical – With medical and laboratory equipment, it is essential that important results can be reproduced accurately and the paper used is very durable and suitability for ultra high-speed printers. In antenatal diagnostics, for example, some records have to be kept until the patient comes of age. Video printer synthetic thermal paper used in ultrasound medical imaging printer. It usually has significantly improved image stability (image durability is longer) over papers formulated for normal use, such as retailers’ receipts.

Security – Thermal paper can be made almost completely forgery proof. This is an important factor in it becoming the paper of choice for admission tickets. A simple tear makes it possible to check whether the document or ticket is genuine.

Wellden's Thermal Paper Grades

We offered commodity and wide range of specialties thermal grades. Our paper is white, very smooth and image is very black (very even image) compare with others. There is no residue to the print head thus no damage and lasts longer (no abrasion). They are very strong on the non fax grades to suit for different market segment and application. The price of our POS/ Fax grade is one of the highest among all. Thermal papers with FSC certified are available upon request and all our topcoated thermal paper are come with BPA free.

Grade A paper for POS

- with BPA and BPA Free contains

- uniform, smooth coat surface = uniform blackening

- no fouling of the print head

- no abrasion, so the print heads last longer

- 5 to 7 years image durability

- paper line up from 48gsm to 70gsm

Grade B paper for POS

- less smoothness compare to Grade A paper

- no fouling of the print head

- less abrasion

- 1 to 3 years image durability

- paper line up from 48gsm to 70gsm

Q&A

How does thermal Paper work?

Thermal papers are coated with a colorless formula which will develop an image by the application of heat. When passing through an image device, precise measures of heat applied by the printhead cause a reaction that creates a strong dark image on the paper.

What are the benefits of Direct Thermal Paper?

Thermal printing technology offers the benefits of clear legible imaging, fast printing, quiet operation, reliability, and low cost of ownership. The are no ribbons or cartridges required.

How do I select the correct direct thermal product for the application?

Wellden's product line is broad and works well in a wide variety of end-use applications.

Is it true that thermal paper images fade or disappear?

There are many types of thermal paper designed for a variety of applications. Some products are formulated for long image life and others are designed to balance economy and short duration use. The life of the image depend on two critical selections. Ensuring that the paper is matched to the thermal printer such that the image color is fully developed is critical. The second is selecting the appropriate grade to match the needs of the end user. For example, thermal products designed for airline ticketing or high life receipts have significantly improved image stability over products formulated for short duration labels or grocery receipts. Image life can be greatly improved, to seven years or longer, by selecting the appropriate grade for the application and adhering to the mill storage recommendations.

Can direct thermal be printed?

Wellden offered wide range of thermal paper suitable to printed with Flexo, UV and offset printing methods.

Others

please share and ask questions